Tolerance Stackup Analysis

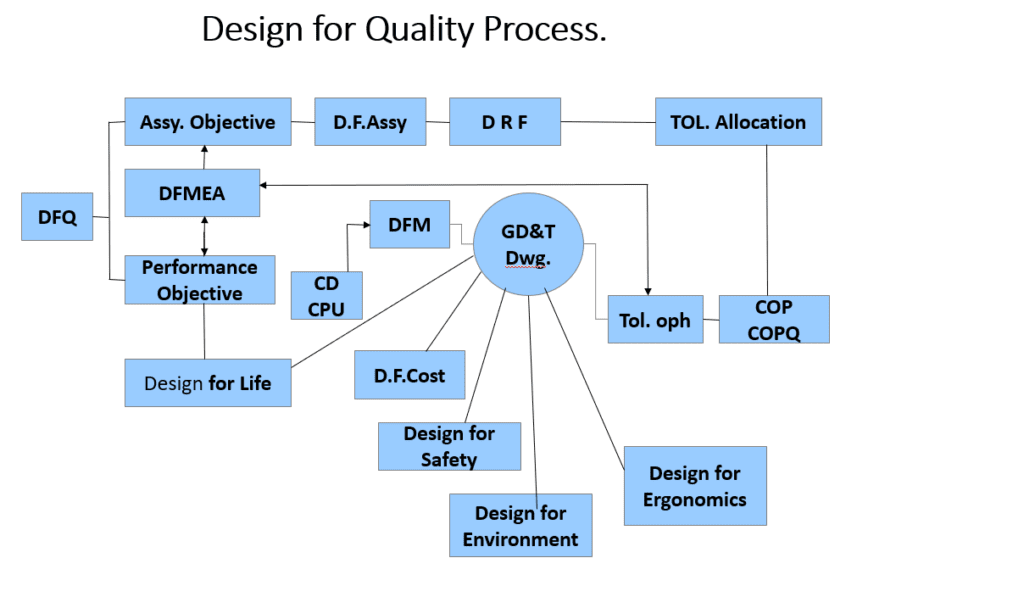

G D & T and Tolerance Stack Up Analysis Services from EGS India

Manufacturing Industry looks to reduce costs and increase profitability. Unambiguous expression of Design Specification is possible by incorporating G D & T (Geometric Dimensioning and Tolerancing ) in the Design process.

EGS India performs Drawing Generation, Interpretation and Prediction of Assembly Build and Performance:

- Development of G D & T Drawings per ASME Y 14.5 / ISO Standards

- Conversion of Plus/ Minus Toleranced Drawings to GD&T Drawings

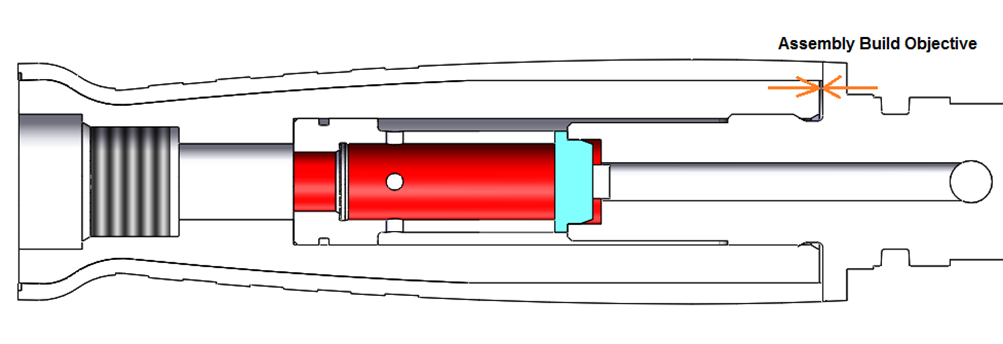

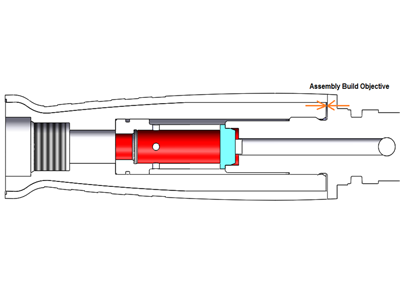

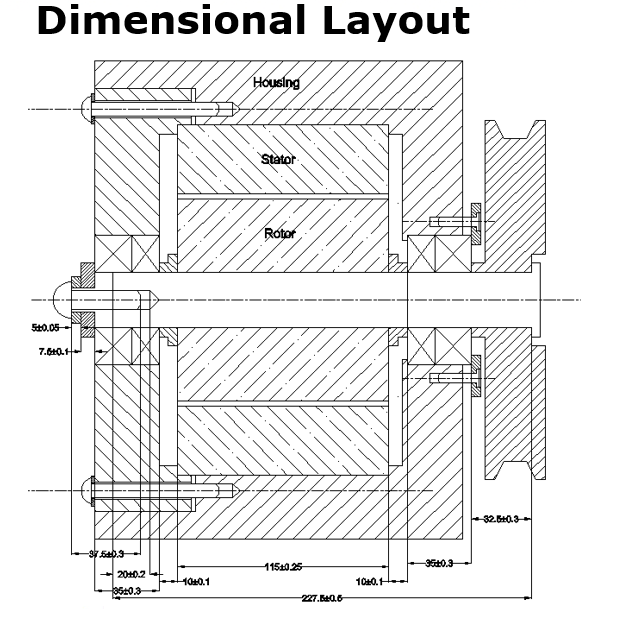

- 1-D, 2-D and 3-D tolerance stack up analysis which is to predict Assembly Build and Performance

- Worst Case Tolerance Analysis can be identified with Inteference Check for predicting Build Issues

- Least Cost Tolerancing of parts to protect assembly build and function based on Process Capability available in the Organization

- Optimization of Tolerances for Least-Cost

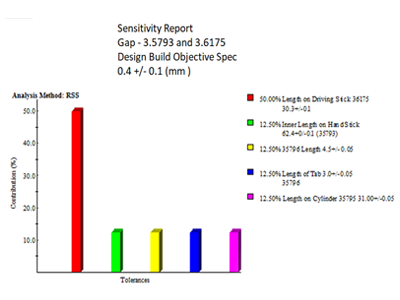

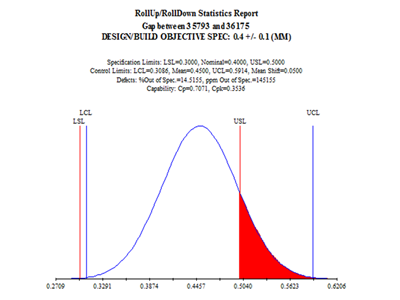

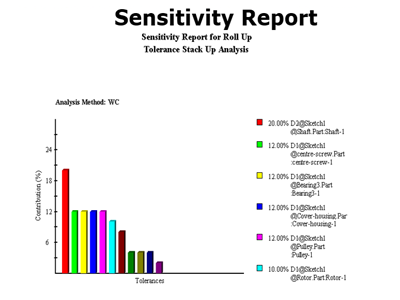

- Sensitivity Analysis of Tolerances for specified objectives in Assembly and Performance

- Specification of Inspection Dimensions for Quality Control

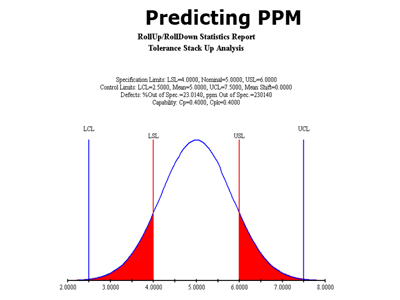

- Prediction of Rejection in terms of PPM based on available process capability

5 Steps to GD&T Enabled Drawings for Higher Product Quality and Lower Cost

Comments are closed.