Machine Design

Machine Design Validation using SOLIDWORKS Simulation – Sales and Technical Support in India since 1997

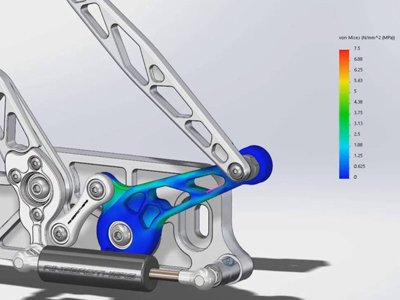

SOLIDWORKS Simulation is the most popular validation software among machine designers involved in design and development of ingenuous systems performing complex functions. When feasibility, efficiency and reliability challenges require to be addressed, SOLIDWORKS Simulation has always delivered without any compromise on cost and functionality. A partial list of SOLIDWORKS Simulation usage in the machine building industry are provided as under:

- Stiffness (deflection) and stress calculations of load-bearing members

- Frequency and Vibration estimation for machine spindles and power train

- Kinematic simulations of mechanisms involving lower (such as revolute, prismatic) and higher-order pair (gears and cams)

- Infinite life designs of high-speed actuation systems

- Strength and durability calculations for presses, machining centres, fixtures, positioning devices, hydraulic and pneumatic actuators, structural sub-systems among others

- Bearing, cam-follower contact load calculations

- Gearbox stiffness and vibration calculations

SOLIDWORKS Simulation application in Machine Design

SOLIDWORKS Simulation has been proven for design validation of many machines. Some of them include:

- Machining Centres

- Special Purpose Machines

- Heavy Engineering machines used in Mining and Crushing

- General Purpose Machines

SOLIDWORKS Simulation can be used to determine:

- Stresses and Deflections in machine load bearing members and work holding devices

- Natural Frequency and Velocities/ Accelerations due to operational requirements

- Ability to achieve tolerances during machining operations

- Stiffness and deflections of machining spindles

- Kinematic analysis of Drive Train using SOLIDWORKS Motion

- Selective Optimization to reduce cost and weight

- Fatigue Life prediction and Failure Mode estimation of load-bearing members and components

Comments are closed.