In SOLIDWORKS, setting up sheet metal parts has become a bit easier, making it possible to automate bend allowance selection by linking materials & sheet metal parameters. With the use of custom materials, you can set the bend allowances to change based on a range of values. This new feature can streamline & standardize the sheet metal part-making process. Let’s see how it works!

Setting Up Your Custom Material

The first thing you would need to do is to set up our custom material, and learn more about creating SOLIDWORKS custom materials. For this example, I copied the material profile of the Aluminium 1060 Alloy.

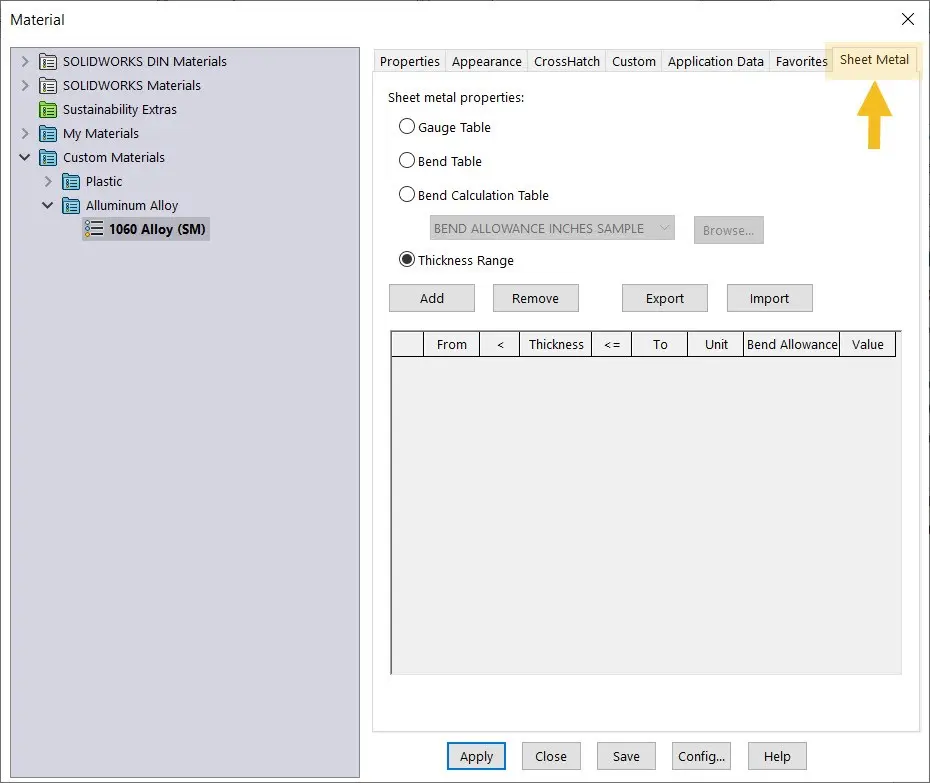

Once completed you may have noticed a Sheet Metal tab as seen below.

Material Sheet Metal Tab

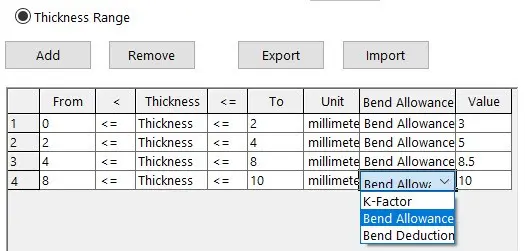

From here you will be able to add sheet metal properties by using Gauge Tables, Bend Tables, or Thickness Ranges. I will focus on the Thickness Range option. From here you can define the range by creating a table like the one shown below.

Thickness Range Table

You will notice that you can define the units, range type, units & bend allowance using the drop-down menu.

One point that must be noted is that the range in this table must be continuous. In other words, if for example you would like to define a range between 1 & 12, all values need a definition. So you cannot have a range from 1-6, then 8-12, because you are neglecting values between 6 & 8.

Applying Sheet Metal Properties from Material

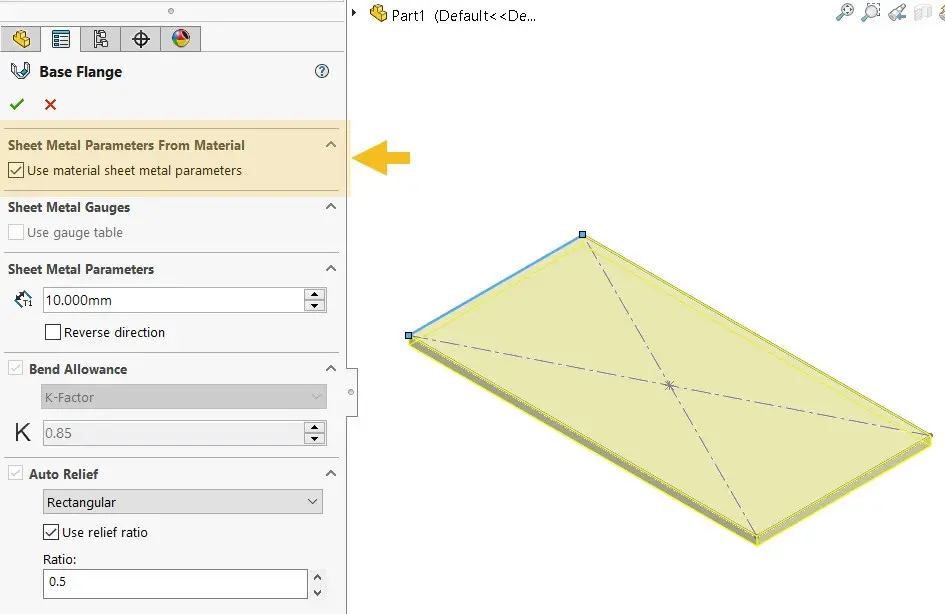

When setting up your sheet metal part, you will notice that you will need to toggle the “Use material sheet metal parameters” as seen below.

Sheet Metal Parameters from Material

Once toggled, you will notice that when you define the thickness, the Bend Allowance will change with it.

What to keep in mind when setting up Sheet Metal Parameters in Materials

- You can only apply these changes to Custom Materials.

- The thickness range must be continuous, covering all values between the Max & Min thickness’s.

Defining the bend allowance at the material level is a great tool that you can utilize in the sheet metal part design work flow. It can unburden the designer when selecting a thickness when creating parts, and it provides another way to manage our sheet metal parameters.

Comments are closed.