Aerospace, Naval, Space, Defence Applications.

Aerospace Applications – SOLIDWORKS Simulation from EGS India – Authorised VAR in Chennai,Coimbatore

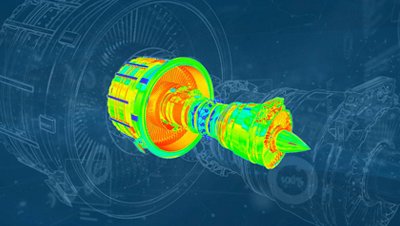

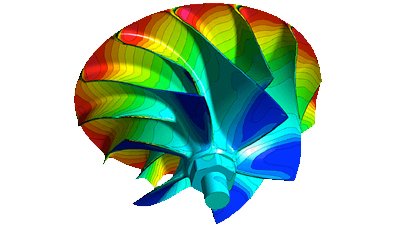

SOLIDWORKS Simulation (Cosmos FEA), from Dassault Systemes SOLIDWORKS Corp. USA, has been used by Aerospace Industry for FEA, for wide-ranging applications involving kinematic analysis, finite element analysis and Computational Fluid Dynamics. Some of the capabilities include:

- Composite Structures FEA

- Shock and Vibration FEA calculations (NAVSEA, MIL STD)

- Durability and Fatigue Life Estimation

- Modal Analysis and Frequency response calculations

- Weight Reduction and Shape Optimization

- Force estimations in Actuators, Mechanisms and Complex Mechanical Devices

- Cooling and Thermal Management of Avionics, Electronic Cooling Systems

- Structural Strength and Buckling calculations

- Non-Linear FEA of Elastomers and Composites

Advantages of SOLIDWORKS Simulation for Aerospace Applications

- Stress calculations on components and sub-systems

- Kinematic Analysis using SOLIDWORKS Motion for mechanisms such as landing gear, door-closure, actuating levers, remotely controlled devices

- Non-linear Simulation of Elastomers, Seals, Gaskets, re-inforced rubber components for strains, performance, durability, sealing effectiveness, pressure foot-print, deflections

- Stiffness, Durability, Tri-axial / Random Vibration and Life estimation for aerospace components such as mounts

- Stiffness and strain calculations for Composite Panels

- Life Calculations of safety systems

- Fluid Flow calculations for valves,pumps, pressure-regulating devices

Return on Investment using SOLIDWORKS Simulation has been the highest among contemporary FEA Software. Design Optimization based on CAD models is easily accomplished in native CAD environment resulting in reduced time and cost.

Comparison with Contemporary FEA Software

| Feautures | SOLIDWORKS Simulation | Other FEA |

|---|---|---|

| CAD Integrated FEA | Limited or Expensive | |

| Design Scenarios | ||

| Easy to Use | Known as not easy to use | |

| CAD driven Optimization | ||

| Analysis to test correlation using ‘soft’ ‘Sensors’ | ||

| CAD Integrated Kinematic Analysi | ||

| Automatic transfer of loads from Kinematic Analysis to FEA |

SOLIDWORKS Simulation in Space Applications

SOLIDWORKS Simulation has been used in design and validation of Space Instruments, Launch Vehicle sub-systems, Satellite sub-systems by Aerospace corporations world-wide.

Some of the areas of application include:

- Validation for Launch conditions including stress calculations, vibration response and life usage

- Weight reduction of satellite components for achieving payload targets

- Failure mode prediction for mission critical components and sub-systems

- Kinematic simulation of actuation systems such as deployment of antenna, solar panels and other devices

Why Choose SOLIDWORKS Simulation FEA Software for Product Design & Development?

- Proven FEA Software for Design and Development of Value Engineered Products

- Inter-operability with any CAD System such as Pro/Engineer (Creo) , Siemens NX (Unigraphics), Autodesk Inventor, Dassault Systemes

- CATIA, Solid Edge 3D CAD

- FEA Translators for NASTRAN, Dassault Systemes SIMULIA ABAQUS, SDRC IDEAS, ANSYS, PATRAN

- True Contact Analysis for Multi-Part Assemblies

- Ability to Solve Very Large Degrees of Freedom (DOF) problems

- h- and p- FEA for accuracy and speed of solution

- Extensive Correlation between Analysis data and Real-World Testing

- Technical Support on FEA Software from EGS India – Engineering Design Consultants since 1993

Comments are closed.